No products in the cart.

Blogs

Where is Audi made? Unveiling Audi’s Global Manufacturing Network

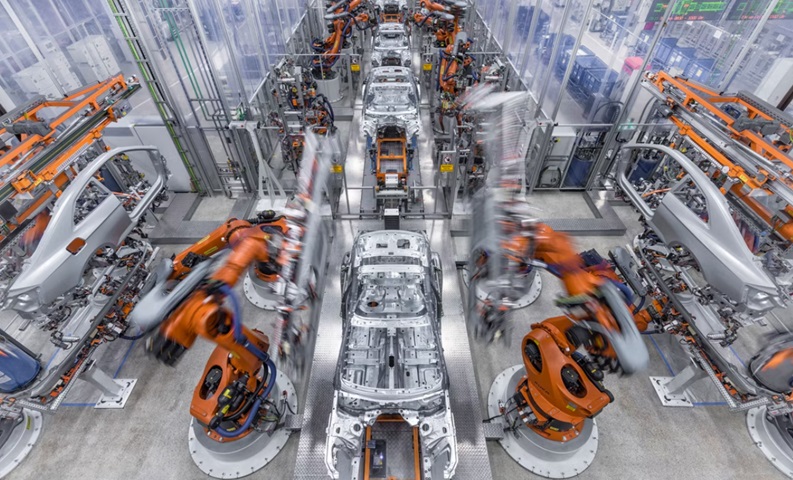

If you’ve ever admired an Audi for its sleek design and German engineering prowess, you might have wondered, “Where exactly is this masterpiece crafted?” The journey of an Audi from concept to the road encompasses a rich tapestry of global manufacturing excellence rooted deeply in tradition and innovation. From the bustling heart of Germany to the far reaches of Asia and America, Audi’s manufacturing sites are a testament to its commitment to quality and the seamless blend of heritage and technology that defines its cars. Join us as we delve deeper into the fascinating world of Audi production.

Origins of Audi manufacturing

The history of Audi’s manufacturing is as intricate and refined as the cars themselves. The brand’s journey began in 1909 when August Horch founded the company, initially producing cars in Zwickau, Germany. The name ‘Audi’ itself carries a historical resonance, derived from the Latin translation of Horch’s surname, meaning “listen” a nod to the brand’s German roots and its emphasis on precision and attention to detail.

In 1932, the brand became part of Auto Union AG, a merger with three other companies: Horch, DKW, and Wanderer. This union gave birth to Audi’s iconic four rings logo, symbolizing this collaboration. The post-war years saw Audi navigating the complex tides of the automotive industry, undergoing several transformations and technological innovations to reestablish itself as a contender in the luxury segment.

The rebirth of the brand can be traced to its acquisition by Volkswagen in the 1960s, sparking a period of renaissance that spurred on innovations in design and engineering. This era marked the introduction of the Audi 100, a model that set the tone for future Audi vehicles with its advanced engineering and high-quality build.

The subsequent decades saw Audi expanding its horizons beyond German borders, driven by a vision to create a global brand synonymous with luxury and precision. Audis gradual shift towards premium and sports models, balanced with advances in technology, made it a potent symbol of successful automaking. Its ability to maintain tradition while innovating has kept Audi relevant and revered in the automotive industry.

Where is Audi made? Primary Audi production facilities

Audi’s primary production facilities are primarily concentrated in Germany, underscoring the company’s strong roots in German engineering excellence. These facilities are at the core of its manufacturing operation, ensuring that each vehicle meets the highest quality standards before leaving the factory floor.

The Ingolstadt facility, established in 1949, stands as Audi’s largest and most vital production hub. It is a giant in automotive manufacturing, producing a range of models, including the Audi A3, A4, A5, and Q2. This plant is not only a testament to Audi’s commitment to quality but also a model of cutting-edge manufacturing practices. With its advanced production lines and dedicated workforce, Ingolstadt sets the benchmark for efficiency and precision.

Neckarsulm, another significant plant, takes pride in crafting Audi’s high-end models. This facility produces luxury vehicles such as the A6, A7, A8, and the high-performance R8 sports car. Known for its meticulous attention to detail, Neckarsulm reflects Audi’s dedication to craftsmanship, seamlessly blending artisanal techniques with state-of-the-art technology.

Beyond Germany, Audi’s global expansion includes facilities in Hungary and Belgium, further bolstering its production capabilities. The Győr plant in Hungary plays a crucial role in manufacturing engines and assembling models like the TT and A3. This site’s strategic location helps streamline Audi’s supply chain, underscoring its global approach to vehicle production.

The Brussels plant in Belgium marks Audi’s foray into electric mobility, producing the all-electric e-tron models. This facility is a shining example of sustainability, having achieved CO2-neutral status, aligning with Audi’s broader goal of reducing its carbon footprint globally.

Countries where Audi cars are produced

Audi’s production footprint extends well beyond Germany, ensuring that the brand can meet the demands of a global audience while adhering to regional preferences. Its strategic international presence is a testament to its adaptability and commitment to maintaining high-quality craftsmanship across all markets.

In Hungary, the Audi plant in Győr focuses on producing engines and assembling models such as the Audi TT and A3. This facility is key to Audi’s global engine supply chain and symbolizes the brand’s dedication to manufacturing excellence, combining innovative production techniques with skilled workforce expertise.

Belgium plays a crucial role in Audi’s transition towards electric vehicles. The Brussels plant is responsible for producing the Audi e-tron, marking Audi’s commitment to a greener, more sustainable future. This site stands out not just for its product but also for its production methods, achieving CO2-neutral status while setting a new standard for environmentally conscious manufacturing.

In the Americas, Mexico’s San José Chiapa facility is pivotal for Audi’s presence in the western hemisphere. This plant specializes in producing the Q5 SUV, using advanced production technologies tailored to the demands of the local market. Its high-altitude location presents unique manufacturing challenges, yet it exemplifies Audi’s capacity to adapt and maintain quality across global environments.

China emerges as a central player in Audi’s Asian production strategy. Through partnerships with local manufacturers like FAW Group, Audi produces various models specifically designed to cater to Chinese consumer preferences. This localization strategy not only reflects Audi’s commitment to meeting local demands but also its ability to seamlessly integrate into varied cultural and industrial contexts.

Comparison of Audi manufacturing plants

Comparing Audi’s manufacturing plants around the world involves understanding their unique capabilities, how they contribute to Audi’s overall production strategy, and how they model innovation and quality across different regions.

Germany

- Ingolstadt: The technological heart of Audi’s production chain, focusing on efficiency and precision.

- Neckarsulm: Specializing in luxury and high-performance vehicles, emphasizing craftsmanship.

Hungary

- Focuses on engines and specific model assembly.

Belgium

- Pioneers Audi’s electric vehicle production, setting eco-friendly standards.

Mexico

- Key for the Americas, producing versatile SUVs tailored to regional conditions.

China

- Produces market-specific models, reflecting local consumer preferences.

Each plant’s strategic role is defined by not only the models produced but also the regional needs it caters to, ensuring that Audi’s global supply chain operates smoothly and efficiently.

Key cities for Audi production

In mapping out the key cities involved in Audi’s production, Germany’s Ingolstadt and Neckarsulm take precedence, being pivotal hubs for producing a significant portion of Audi’s lineup. Ingolstadt represents the future-proof strategies with innovations like the integration of AI in manufacturing processes which dictate Audi’s high standards of efficiency and quality.

Neckarsulm is synonymous with sophistication and top-tier engineering. Known for its high performance and luxury model production, it seamlessly integrates cutting-edge technology and meticulous craftsmanship, thereby setting benchmarks for qualitative outcomes in the industry.

Expanding further into Europe, the city of Brussels is iconic for its focus on Audi’s shift towards electric mobility. The city not only promotes a greener vision for the brand but also encompasses Audi’s dedication to sustainable manufacturing practices. Győr, too, is indispensable, fortifying Audi’s focus on advanced engine technologies and innovation.

In the Americas, San José Chiapa signifies Audi’s strategic expansion into the western hemisphere, primarily producing the popular Q5 SUV. The city leverages its geographical advantage, serving as a gateway for the brand to cater to both South American and North American markets effectively.

Asia sees cities such as Changchun rise, emblematic of Audi’s production strategy in accordance with specific market needs. Through its alliances with local car manufacturers, Audi tailors its production to suit regional consumer behaviors and demands.

Audi factory locations in Europe

Audi’s European production network extends beyond the boundaries of Germany, deeply embedding itself within the continent’s industrial landscape. In Belgium, the Brussels plant stands out for its dedication to manufacturing Audi’s sustainable e-tron models. This site reflects Audi’s unwavering commitment to the development of electric vehicles, representing a shift towards more environmentally friendly production methods.

Hungary homes the Győr plant, an epicenter for engine manufacture and assembly. This facility underscores Audi’s allegiance to cutting-edge technology as it supports a significant proportion of the engine supply chain. Its dynamic production techniques set Győr apart as a beacon of efficiency and technological advancement within Audi’s European production lineup.

Spain, with its shared site with SEAT in Martorell, becomes a crucial part of Audi’s European production strategy. This plant, known for the Audi Q3, symbolizes synergies within the Volkswagen Group and allows for an adaptable production environment that meets the ever-evolving demands of the European market.

This extensive network of facilities helps maintain Audi’s stronghold in Europe, ensuring that production quality and innovation grow hand-in-hand with the brand’s legacy on the continent.

Audi production in North America

In North America, Audi’s presence is marked by significant strategic developments, with Mexico as a critical hub. The San José Chiapa plant symbolizes Audi’s expansion into the region, focusing on producing the popular Q5 model, specifically engineered to face the challenges of the area’s unique climate and altitudes.

Audi’s plans for expansion into the United States highlight the brand’s ambition to enhance market penetration within North America. The Volkswagen Group’s existing plant in Chattanooga, Tennessee, alongside potential new facilities, could serve as future centers for Audi production in the U.S. such plans unfold, which would allow Audi to leverage domestic manufacturing for the North American market, thereby reducing any tariff-related costs and increasing operational efficiency.

The potential alliance with Scout Motors for a plant in South Carolina reflects ongoing strategic evaluations, considering models like the Q8 e-tron and the upcoming Q6 e-tron. These initiatives reinforce Audi’s expanding North American footprint, aiming to address specific consumer preferences through tailored, locally-focused production strategies.

Audi production in Asia

Asia represents a significant and rapidly evolving market for Audi, where the brand has taken strategic steps to establish a substantial production presence. In China, Audi’s partnership with FAW Group exemplifies how local joint ventures can effectively address domestic market preferences. This collaboration highlights Audi’s commitment to integrating into the world’s largest automotive market, producing models that directly cater to Chinese consumers.

India marks another important piece of the puzzle within Asia, with its production facility in Maharashtra. This plant contributes significantly to the local market by manufacturing key models, including the Audi A4 and Audi Q3. India’s role in Audi’s production strategy accentuates the brand’s adaptive strategies to meet diverse market requisites, balancing quality with local manufacturing capabilities.

The success of Audi’s production in Asia is anchored in its understanding of regional consumer preferences and rigorous quality control, ensuring that every car produced resonates with Audi’s hallmark of precision and innovation. This region continues to be a focal point for Audi’s strategic manufacturing goals, driving future growth in the rapidly evolving Asian automotive landscape.

Audi’s global manufacturing strategy

Audi’s global manufacturing strategy is a nuanced interplay of precision engineering, sustainable practices, and regional adaptation. It emphasizes localization, ensuring that production sites not only meet global standards of quality but are also tailored to accommodate market-specific demands, minimizing supply chain disruptions, and maximizing efficiency.

Audi has implemented a localization strategy, sourcing automotive components closer to factories to enhance supply chain efficiency. This pivot increases resilience, reduces costs, and shortens lead times, crucial for maintaining a competitive advantage. The strategy aligns with Audi’s commitment to sustainability, reducing its carbon footprint by shortening transportation routes.

This strategy has been instrumental in structuring a network of production facilities, such as those in Germany, which retain the heart of Audi’s engineering prowess, and extending into countries like Hungary, Belgium, Mexico, and China. Each facility, while following standardized production protocols, adapts to local market demands, thereby ensuring that the Audi model lineup appeals to consumers across diverse markets.

This global strategy underlines Audi’s emphasis on crafting high-quality products that instill the essence of German engineering, whether produced in the bustling factories of Ingolstadt or the innovative Brussels plant. By maintaining standardized practices across a globally spread production network, Audi ensures consistency in quality and performance, reinforcing its reputation as a leader in the premium automotive market.

Impact of localization on Audi manufacturing

The push for localization has significantly transformed Audi’s manufacturing methodology. By focusing on producing components nearer to the factories, Audi not only reduces lead times but also mitigates potential disruptions caused by crises such as the COVID-19 pandemic. This strategic shift towards localization ensures that Audi remains agile in its production capabilities, capable of meeting market demands efficiently and cost-effectively.

Localization supports Audi’s broader sustainability goals by minimizing transportation routes, leading to a reduced carbon footprint. Harmonizing local component sourcing with car production allows for more sustainable operations, aligning with Audi’s aim for net carbon neutrality by 2025.

This approach has also optimized inventory management, as proximity to suppliers enables a just-in-time production system, minimizing storage costs and waste. Additionally, localization fosters closer partnerships with suppliers, driving co-innovation in component design and manufacturing processes, a win-win for all parties involved.

Audi’s commitment to a localized manufacturing network does not only involve strategic business decisions; it also solidifies the brand’s role in supporting local economies, bolstering economic growth in regions where they operate. As they continue to diversify and expand their production base in alignment with local preferences, Audi stands out as a model for balancing global brand integrity with regional relevance.

Future trends in Audi production locations

As Audi looks towards the future, electrification and sustainability have become integral components of its production strategy. By 2029, Audi aims to ensure that all global production sites manufacture exclusively all-electric vehicles, signifying a bold move towards reducing environmental impact and promoting greener transport solutions.

Investments in advanced manufacturing technologies like AI and automation underscore Audi’s forward-thinking approach. With over 100 AI projects underway, the company leverages technology to drive factory efficiency and product quality, using real-time data to optimize manufacturing processes.

Audi is also focusing on enhancing workforce development, equipping employees with the skills needed for next-generation production methods. This investment in human capital is essential for empowering its workforce to adapt to advancements and maintain Audi’s high-quality standards amidst changing technological landscapes.

Furthermore, Audi’s attention to sustainability is reflected in initiatives to achieve carbon neutrality across all production facilities by 2025. This includes implementing energy-efficient technologies and maximizing the use of renewable resources, establishing Audi as a leader in the automotive industry’s shift toward eco-friendly practices.

By marrying technological innovation with strategic sustainability measures, Audi ensures its production locations remain at the forefront of the automotive industry’s evolution, committed not only to the future of mobility but to the well-being of the planet as well.

FAQs

Where is Audi’s largest production facility located?

Audi’s largest production facility is located in Ingolstadt, Germany.What model is produced in Audi’s Brussels plant?

The Brussels plant is dedicated to producing the all-electric Audi e-tron.Are Audi cars produced in the United States?

Currently, Audi does not have production facilities in the United States but is exploring potential manufacturing sites.What is the focus of Audi’s manufacturing strategy?

Audi’s strategy focuses on electrification, sustainability, and advanced manufacturing technologies to maintain high-quality standards.How is Audi addressing market-specific demands in Asia?

Audi addresses market-specific demands in Asia through partnerships with local manufacturers, producing models tailored to regional consumer preferences.

Key Takeaways

- Audi’s production origins are rooted deeply in German engineering, with a rich history dating back to 1909.

- Primary production facilities are centered in Germany, with significant plants in Ingolstadt and Neckarsulm.

- Audi adapts to global demands with production facilities in Europe, North America, and Asia.

- The brand emphasizes localization, enhancing efficiency and minimizing environmental impact.

- Audi’s future trends focus on sustainability and advancing AI-driven manufacturing practices.

Conclusion

Audi’s manufacturing journey is a complex tapestry interwoven with threads of innovation, quality, and tradition. From its historical roots in Germany to its far-reaching global facilities, Audi’s commitment to excellence permeates every aspect of its production process. By embracing localization, advanced technologies, and a sustainable future, Audi not only embodies the pinnacle of German engineering but stands as a beacon of modern manufacturing strategies. As the company propels into an electrified era, balancing eco-conscious initiatives with technological breakthroughs, Audi continues to uphold its legacy of producing vehicles that are not just means of transportation but symbols of prestige and innovation.