No products in the cart.

Blogs

Where is Volvo Made?

Volvo, the iconic Swedish brand, is synonymous with engineering excellence and a relentless commitment to sustainability. Though its roots are firmly planted in Sweden, Volvo’s manufacturing tentacles stretch across the globe, ensuring delivery of quality vehicles wrapped in Scandinavian style to international markets. This article delves into the core of Volvo’s manufacturing operations that not only keep the brand a step ahead in the fiercely competitive automotive industry but also highlight Volvo’s strategic distribution of its production base to enhance operational efficiency and market responsiveness.

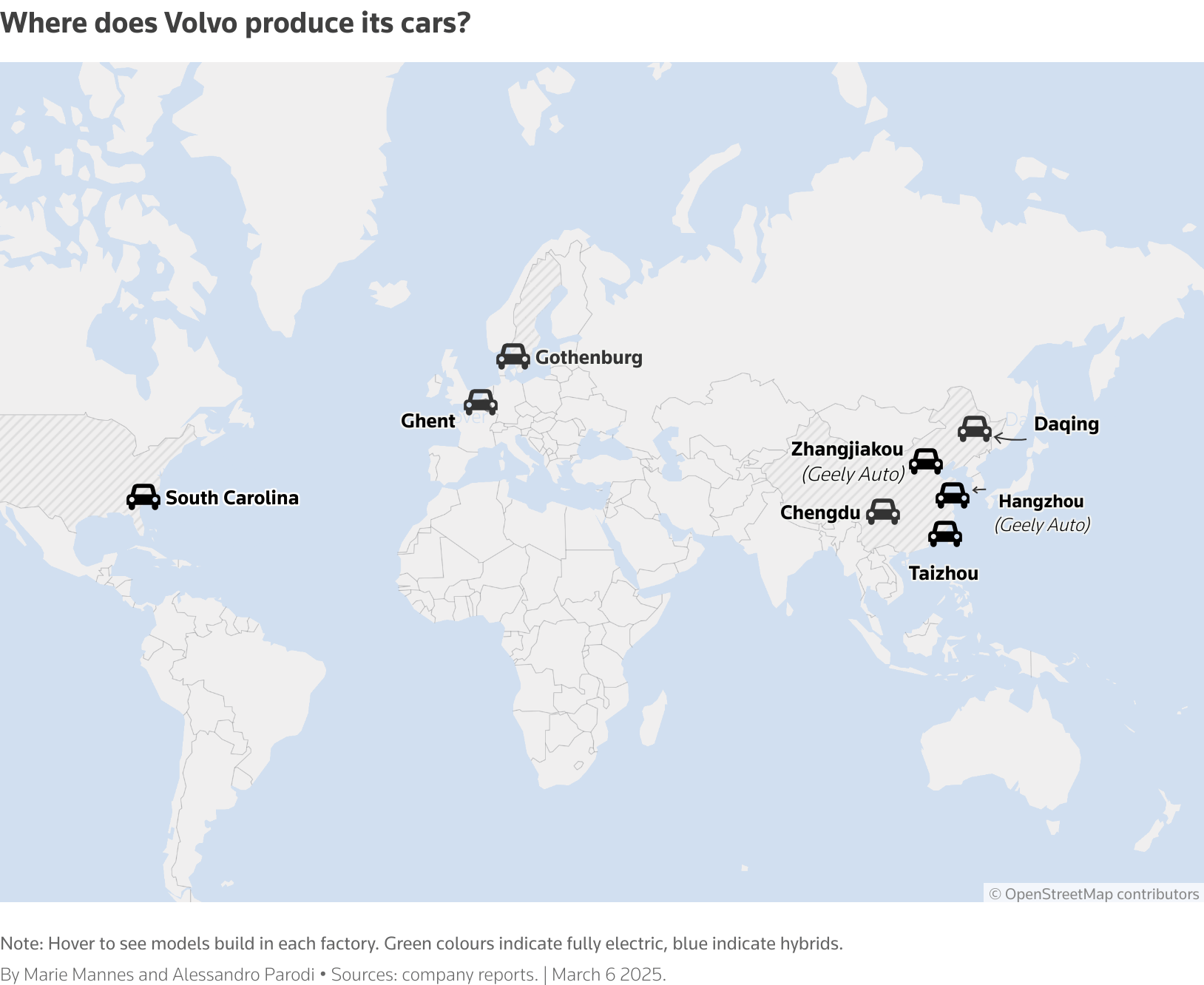

Where is Volvo made? Volvo Manufacturing Locations

Volvo’s manufacturing prowess is not limited to the Scandinavian Peninsula. With significant production footprints in Europe, Asia, and the Americas, Volvo has cemented its presence globally. This strategic manufacturing diversification underpins Volvo’s commitment to providing quality vehicles efficiently while adhering to stringent sustainable practices across all locations.

Sweden: The Home of Volvo

In Sweden, Volvo’s presence is both historical and substantial. The Torslanda plant in Gothenburg is the flagship facility, where about 300,000 vehicles roll out annually, showcasing models like the XC90 with unmatched craftsmanship. Here, high energy efficiency and sustainable practices are the plant’s hallmark. The Swedish influence pervades all aspects of manufacturing from the precision of robotic arms over 1,400, to be precise to the innovative methods adopted for production. A significant contribution from the Gothenburg plant is its achievement in climate neutrality, using renewable energy sources, like biogas.

Sweden hosts not only Volvo’s production sites but also advanced research and development centers crucial for driving innovation. These include a joint battery manufacturing plant with Northvolt, slated to propel Volvo towards its all-electric vehicle ambition by 2030. Key to Volvo’s operation, the Tuve plant, focuses on producing heavy-duty trucks like the FH and FMX, advocating Volvo’s diversification in vehicle types.

The emphasis on standard and quality in Swedish facilities supports Volvo’s ambition of leading in both luxury and sustainability. Abundance in natural resources and a strong engineering legacy have transformed Sweden into a fertile ground for Volvo’s thriving manufacturing activities. Moreover, Sweden stands as a beacon for innovative practices and stringent quality control as evidenced by the innumerable awards bagged by Volvo for its precision manufacturing techniques and its global contributions toward sustainability.

Belgium: European Manufacturing Hub

Belgium is home to one of Volvo’s most advanced facilities located in Ghent. The Ghent plant stands out not only for its scale but also for its technological advancements. It employs cutting-edge technology to facilitate efficient production of models like the XC40. Significantly, the plant has made substantial strides in electrification; with a mere 79 seconds taken to roll a vehicle off the line, it emphasizes high production efficacy amidst sustainability goals.

In recent years, Ghent has emerged as a central hub for Volvo’s electric vehicle (EV) journey, marked by the addition of a state-of-the-art battery assembly line. By doing so, the plant has paved the way for EV models, aligning perfectly with Volvo’s plans for reducing CO2 emissions, promising climate neutrality by 2040. Ghent’s story is one of a rapid transition from a traditional manufacturing site to an electrification powerhouse.

The focus in Belgium remains heavily on sustainability, pushing forward an agenda that envisions significant job creation approximately 350 jobs tied to the lucrative production of the upcoming EX30 model. This synergy of European strategy and innovative plant infrastructure makes Ghent indispensable to Volvo’s global manufacturing operations.

China: Expanding Production Capacity

China represents a burgeoning automotive market, and Volvo has strategically expanded its manufacturing capacities here to meet the rising demand. With facilities in Chengdu and Daqing, Volvo has firmly planted its flag in the Asian continent. These plants are extensively involved in producing popular models like the S60 and XC60, which cater both domestically and internationally.

The Daqing plant, operational since 2014, focuses heavily on exporting models like the S90 to Europe. The commitment to quality and competence in Daqing mirrors that of its Western counterparts. Meanwhile, Chengdu emphasizes the adjustment of Volvo’s operations to accommodate local regulations and customer needs while maintaining standardization and quality protocols equivalent to other Volvo facilities worldwide.

Collaborations with Geely, a significant player in the Chinese automotive industry, underscore Volvo’s strategy of localization, making its production more efficient and culturally attuned to the rapidly growing Asian market. The emphasis on adhering to local consumer preferences while maintaining global standards makes Volvo’s China operations a critical linchpin in its international strategy.

Volvo Production Facilities

Volvo’s production facilities across the globe mirror its commitment to quality and sustainability. With each location tailored to specific market requirements yet adhering to uniform quality benchmarks, Volvo leverages regional strengths in manufacturing, ensuring seamless production and innovation.

Plant in Gothenburg, Sweden

The Gothenburg plant is more than just a facility; it’s a reflection of Volvo’s philosophy. Situated in Torslanda, this plant is synonymous with precision and quality. Employing around 6,500 people, it stands as a colossal testament to Volvo’s manufacturing prowess. The landmark facility uses approximately 1,400 robotic arms, ensuring a seamless mix of automation and skilled labor in the production process.

Volvo implements numerous sustainable methods in Gothenburg, such as using biogas and recycling industrial waste for heating underscoring its eco-friendly commitments. This dedication has enabled the plant to reach climate neutrality a remarkable feat by any standard. Such innovation ensures that each model produced here upholds Volvo’s tradition of safety and superior engineering.

Focused production of models like the XC90 reaffirms the plant’s significance. This plant’s output isn’t isolated to Sweden alone but serves as a vital component of Volvo’s product delivery across Germany, the UK, and many other European nations. Notably, the plant has integrated new technologies and modern equipment to host an R&D hub for future Volvo models, including joint ventures like the battery manufacturing plant with Northvolt that promises to revolutionize battery usage in vehicles, accelerating Volvo’s vision of being fully electric by 2030.

Ghent Manufacturing Plant in Belgium

A marvel of modern efficiency, the Ghent plant facilitates optimized production by integrating advanced robotics and assembly lines. This ensures Volvo can maintain its high production standards across Europe. Notably, the production of hybrid and electric models such as the XC40 Recharge aligns with contemporary market needs and highlights the Ghent plant’s adaptability.

Furthermore, the swift production cycle producing a vehicle every 79 seconds coupled with the battery assembly line, makes this facility crucial in meeting rising EV demands. The plant can accommodate different model specifications on a single production line, providing the flexibility required to shift with dynamic consumer preferences.

Investments in Ghent are clearly paying dividends, not just in production efficiency but also in workforce expansion. By focusing on skills enhancement and modern assembly practices, the plant is poised to not only meet but surpass European automotive standards, an endeavor that fortifies Volvo’s market share in the region.

Daqing and Chengdu Plants in China

China’s automotive sector is growing, and Volvo has strategically leveraged its Daqing and Chengdu plants to tap into this robust demand. The Daqing plant, serving as a major export hub especially for the S90, operates with a dedicated commitment to quality, equivalent to any European sister facility, which reinforces Volvo’s universal brand allure.

Chengdu’s pliability lies in its adaptability to local regulations and preferences, producing the S60, XC60, and the new EX30. Volvo ensures that the stringent global quality standards are met, even as local production techniques are adapted for economic and logistical efficiencies. This harmonization of global branding with local operations ensures Volvo’s vehicles resonate well within the Asian market demands.

The collaboration with Geely further signifies Volvo’s commitment to a localized manufacturing strategy that not only enhances its output capabilities but secures strongholds within the world’s largest automotive market. This symbiosis of traditional Volvo values and regional partnerships underlines a comprehensive strategy for sustained growth.

Volvo’s Global Manufacturing Strategy

Volvo’s capacity to adapt its strategy across varied production facilities is key to its global manufacturing success. Each production site strategically caters to specific market needs while retaining Volvo’s hallmark of safety and quality, ensuring efficient production that aligns with environmental commitments.

Global Supply Chain Network

A robust global supply chain is instrumental to Volvo’s diversified manufacturing strategy. The interconnectivity between facilities spans multiple continents, reflecting a seamless integration of logistics, procurement, and distribution centers. By aligning operations across over 60 facilities and maintaining substantial supplier networks, Volvo can mitigate risks associated with global supply chain disruptors.

An inclusive procurement framework comprises 12,000 international suppliers, enhancing the brand’s resilience and competitive edge. The leadership of Francesca Gamboni as Chief Supply Chain Officer further strengthens this network, emphasizing dynamic and sustainable supply chain management as crucial to Volvo’s ongoing success.

The result is a sophisticated operation where efficiency and reliability meet environmental sustainability, substantiating Volvo’s reputation in the competitive automotive industry. Notably, fields such as logistics and supply chain management have increasingly become pivotal, driving continuous improvement and reducing operational footprints across various markets. This sets a benchmark, not only for environmentally-driven growth but also for continuous global supply enhancement.

Localized Production for Different Markets

Volvo strategically focuses on localized production to better serve distinct market demands. Each region’s plant adapts to local customer preferences, regulations, and economic factors, ensuring Volvo’s global quality and safety standards are uniformly adhered to.

For instance, the strategically located Charleston plant in South Carolina addresses the preferences and expectations of the North American market by producing models like the S60 sedan and introducing electric lines such as the EX90 SUV. This localization reduces lead times and enhances market responsiveness, providing flexibility to adapt rapidly to changing consumer trends.

The integration of Eurocentric manufacturing advances in plants like Ghent and Gothenburg balances local market characteristics with world-class engineering. This harmonizes Volvo’s global approach with regional insights, demonstrating a nuanced ability to cater effectively to diverse international markets. This synergy positions Volvo as a brand that transcends geographic barriers, underpinning its stature as a globally trusted automotive leader.

Comparison of Manufacturing Locations

A comparative analysis of Volvo manufacturing locations reveals insightful distinctions that highlight regional strengths and capabilities while maintaining uniform quality and safety standards globally.

Quality and Standards Across Locations

Despite diverse geographic footprints, Volvo’s commitment to unwavering quality and safety standards remains the common thread that ties its global manufacturing operations together. Each facility follows stringent guidelines to meet company standards, whether it is in Sweden, Belgium, China, or the U.S.

These guidelines ensure that no matter where a car is produced, it adheres to the same level of quality, safety, and production excellence recognizable in all Volvo cars. Robot-assisted manufacturing processes, integrated energy-efficient systems, and green initiatives form the backbone of this global alignment.

The drive towards maintaining high standards globally involves a blend of automation, precision engineering, and skilled labor, enhancing uniformity across production lines. Differently located Volvo facilities thus represent focal points of excellence, producing vehicles embodying the brand’s forward-thinking ethos and enduring reliability.

Differences in Production Techniques

While global uniformity in quality is prioritized, localization of production techniques allows Volvo to adapt to regional demands effectively. For instance, using local resources and labor in China helps reduce production costs while still maintaining globally recognized product integrity.

Swedish plants, enriched by high-quality local craftsmanship traditions and a legacy of engineering excellence, utilize this heritage to enhance vehicle production. Contrarily, advanced robotics and assembly techniques dominate facilities in Belgium and North America, facilitating rapid production cycles and flexibility in model adaptations.

These variations do not compromise quality but rather reinforce Volvo’s adaptability to global market dynamics. Such differentiated approaches are essential in maintaining Volvo’s agility in an ever-evolving automotive industry landscape, ensuring a seamless blend of tradition and cutting-edge innovation.

Future of Volvo Manufacturing

Looking ahead, Volvo is poised to redefine automotive manufacturing with a transformative combination of sustainability, technological innovation, and strategic expansion.

Upcoming Facilities and Expansion Plans

Volvo’s future plans embody a formidable mix of growth and technological progression as global demand for its vehicles rises. In North America, Pennsylvania’s Shippensburg facility is earmarked for expansion, set to enhance production of compactors and mid-size loaders by 2026, underpinning local machine supply dominance.

In Slovakia, Volvo’s upcoming EV-exclusive plant is set to operationalize by 2026, playing a critical role in the strategic push towards electrification. This aligns with Volvo’s vision of becoming an all-electric brand by 2030, with facilities engineered to meet heightened EV demand efficiently.

These expansions underscore Volvo’s strategic foresight, providing the infrastructure needed to innovate rapidly. By 2026 and beyond, Volvo’s manufacturing will encompass greater capacity, flexibility, and a steadfast adherence to quality.

Innovations in Manufacturing Processes

Volvo’s embrace of modern technology is a cornerstone of its future evolution in manufacturing. The integration of advanced platforms like 3DEXPERIENCE enhances Volvos production processes for developing next-generation electric vehicles, affirming its commitment to sustainability and efficiency.

Smart factory initiatives exemplify Volvo’s forward thinking, where Industry 4.0 principles blend cutting-edge technologies like the GPSS system, enabling automation and enhanced safety measures within production environments.

As Volvo ventures deeper into electrification and sustainable manufacturing, its ambition to balance traditional craftsmanship with innovative processes promises not only to redefine its own operational excellence but also set new industry standards for what modern automotive manufacturing can achieve.

FAQs

Where is Volvo made? Are Volvo made in China?

Volvo’s main hub is in Gothenburg, Sweden, complemented by significant plants in Belgium and China. So, Yes! Volvo is made in China too but not all.

How does Volvo ensure quality across its global facilities?

Through stringent quality standards and a blend of automation and skilled labor, Volvo maintains consistent quality worldwide.

What role does the Ghent plant play in Volvo’s EV strategy?

Ghent is pivotal for EV production, integrating modern manufacturing techniques and battery lines to advance Volvo’s electrification goals.

Why has Volvo expanded its production facilities in China?

To meet the growing demands of the Asian market while maintaining global production quality and efficiency.

What are Volvo’s future plans for its manufacturing capabilities?

Expansion in North America and Slovakia, focusing on increased EV production and higher manufacturing efficiency by 2026.

Key Takeaways

- Global Manufacturing Footprint: Volvo maintains manufacturing sites in Sweden, Belgium, China, and the USA.

- Emphasis on Sustainability: All facilities focus on eco-friendly practices and climate neutrality.

- Localized Production: Tailored operations to suit regional market demands while adhering to Volvo’s global standards.

- Technological Integration: Adoption of cutting-edge technologies to enhance production efficiency and safety.

- Future Expansion: Planning significant expansions in North America and Europe to bolster EV production.

Conclusion

Volvo’s manufacturing legacy is built on a foundation of quality, innovation, and sustainability, with strategic global sites tailored to serve diverse markets effectively. As the automotive industry evolves, Volvo’s agile adaptation of its manufacturing processes and strategic global distribution ensures consistent delivery of high-quality vehicles reflective of its rich Swedish heritage. Looking to the future, Volvo’s unwavering pursuit of sustainability and innovation uniquely positions it to lead the way in the automotive landscape, with a growth trajectory poised to redefine industry standards.